HISTORY

LINDNER ARMATUREN BETWEEN TRADITION & MODERN AGE

More than 100 years of eventful business history tell about ventures, successful moments and times of crisis. But what has marked Lindner through all of the years are creative product solutions, a close relation to our customers and the courage to break new ground and to set benchmarks.

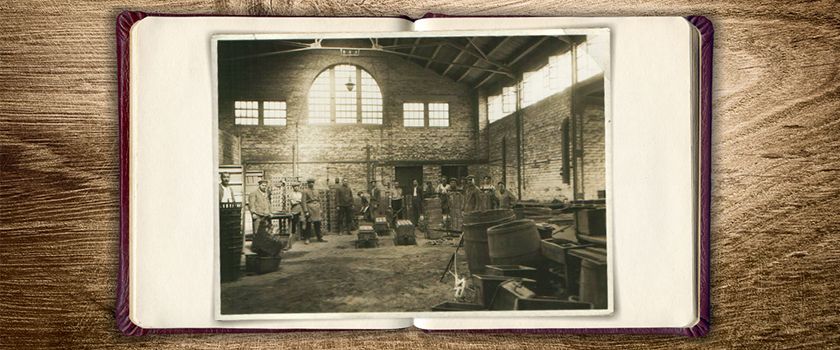

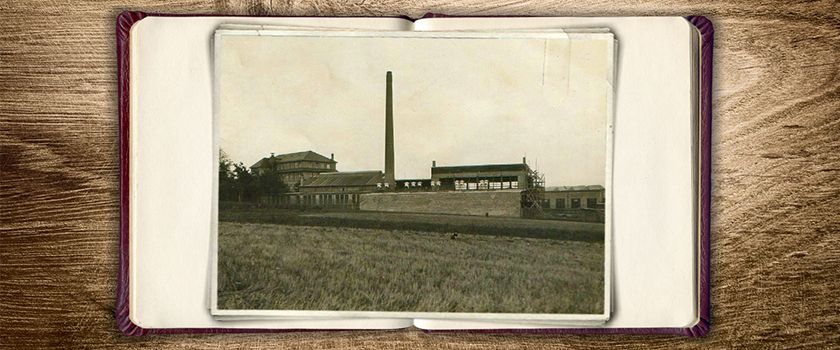

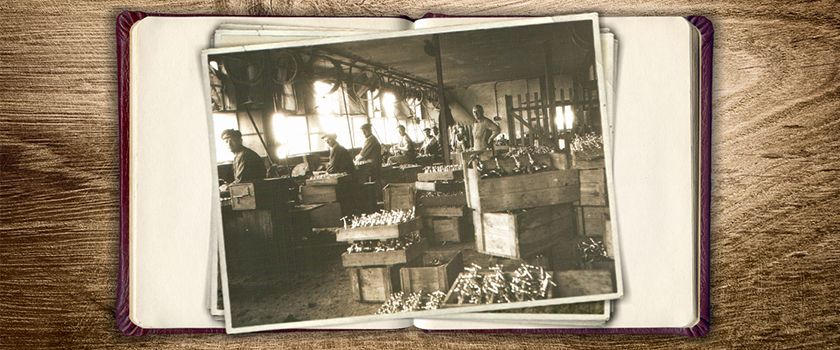

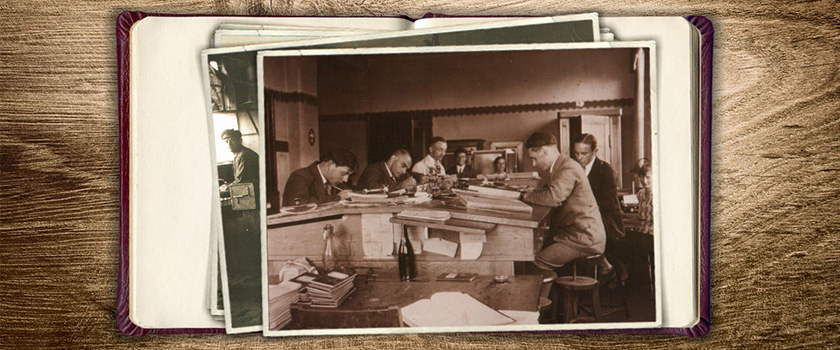

HISTORYThe foundry workers Max and Felix Lindner as well as Paul Boettcher founded the “Armaturenfabrik Lindner & Boettcher, Rabenstein” on December 29th, 1905. After the resignation of Boettcher in 1906 both Lindner brothers continued the business under the name “Lindner & Co. Rabenstein”. Already after a few years the initial production capacities became insufficient, so that a new factory was built in 1914 at the current premises at “Kurze Strasse 10”. In 1925 the erection of a foundry with three melting furnaces folllowed. The number of employees had raised to 180 at that time. Many wholesalers from all over Germany belonged to Lindner’s customers. “Fine taps” for kitchen, bath, cellar and garden as well as gas and industrial valves have been produced until the outbreak of the Second World War. Based on drawbacks of the war the product range changed to simple mass products.

Between 1950 and 1972 the previously family run business had nearly completely been expropriated by the GDR. The governmental shareholding was approximately 80 %. In 1972 the former tap manufactory “Lindner & Co. Rabenstein” had become the nationally-owned entreprise “Armaturenwerk Karl- Marx-Stadt” with 50 employees. Already in 1955 an iron foundry had been established compulsorily since the use of brass had been impeded by governmental limitations. Thus, 500 tons of iron casting and 100 tons of brass casting have been casted and processed annually. However, due to lacking investments mainly with a state of technology from 1930. The transmission drive that had been installed in 1914 when building the factory has been used until 1965. After the expropriation the nationally dictated range of products has been minimised, so that nothing remained from the previous variety of “finest sanitary taps”.

In order to assure governmental orders and thus the existence of the factory, the “Armaturenwerk Karl-Marx-Stadt” had been affiliated to the state combine “Armaturenwerk Eisenberg” in 1975 and was called from then on “nationally-owed entreprise Armaturenwerk Eisenberg Business unit Karl-Marx-Stadt”. Until 1989 / 1990 the formerly well-run private entreprise has been ruined to an economically unviable sub-supplier of inferior products. At June 30th, 1991 all employees were dismissed by the nationally-owned company.

The reprivatisation, which had already been applied for shortly after the disappearance of the inner German border, lasted until January 1993. Nevertheless, Mr Stefan Lindner, grandson of the co-founder Felix Lindner, already started clean-up works in July / August 1991 with the help of former colleagues of the nationally- owned company and owing to the vital support of the company HANSA Armaturen Stuttgart. Besides the outer building shell, the company needed a total gutting and complete refurbishment. The new Lindner Armaturen GmbH, that had been founded on June 28th, 1991, was modernised in only 3 months with an unimagineable commitment of all helpers. This way the company could re-start business on August 12th, 1991 with 10 employees. Initially, all business units from the production to sales to the accounting department had to be re-organised according to modern Western standards. The first large investment was the commissioning of a CNC lathe “Index GB 30”, that improved the production performance and quality of the goods essentially and was soon operated to its full capacity. Further high-performance CNC machining centres followed.

The first products were miscellaneous turned parts as accessories to valves and fittings, since the demand for installation material was quite high within the “New Laender”after Germany’s reunification. Own patented developments as professional distributors, anti-twist wall bushings and cross-fittings for radiator connections followed and made Lindner known and favoured in the market. Since 1994 the brass product line is being completed by the order-bound manufacture of reinforced flexible hoses for heating and sanitary, which shortly became a vital business field of Lindner Armaturen GmbH.

Numerous major customers from a wide range of industries, from the classic fittings industry to apparatus engineering, building services engineering, medical technology and also aeronautical engineering, now rely on high-quality Lindner connection hoses made from a variety of innovative materials. Oxygen diffusion-tight hoses of the O2-Stopp and OXYban brands for chilled ceiling connections are just as much a part of the range as the high-purity polyethylene connection hoses "Lc-flex", which meet the latest hygiene regulations of the German Drinking Water Ordinance. A large selection of connection fittings according to common international standards, special fittings such as John Guest connector systems or the in-house development of the LC connector system as well as individual connection solutions meet almost every customer requirement - whether in individual, small or large series.

Lindner hoses are not only hidden in numerous construction projects such as the Düsseldorf City Gate or the Deutsche Bank towers in Frankfurt, they can also be found in Swiss coffee machines or Airbus aircraft.

In order to optimise the production process of the hoses, a new hall with state-of-the-art production lines, testing and laboratory facilities as well as a warehouse for the individual parts of the range of almost 5,000 variants was inaugurated in 2008. Up to 10,000 hoses can now be produced daily.

The excellent quality of Lindner products has been confirmed by the certified DVGW quality management system according to DIN EN ISO 9001:2015 since 2000.

Lindner has also established itself as a force to be reckoned with internationally. The direct export quota throughout Europe is a constant 30 % and is growing continuously. In addition to its own products, which are marketed in a three-stage distribution channel, Lindner manufactures products for industrial customers in small and large series. Rotationally symmetrical parts and housings are produced with the highest precision. Since 2010, the production of free-form parts has been realised with the latest generation of CNC turning-milling centres such as EMCO or G 200.

The range of services extends from the development of customised product solutions to contract manufacturing according to drawings and the prefabrication of complex assemblies. Turning, milling, bending, flowdrilling, soldering, spinning and extensive assembly services are also available. The in-house toolmaking department quickly and flexibly supplies samples, individual parts, special tools, assembly and testing equipment as well as special machines.

We primarily process brass alloys, of course also lead-free, as well as other non-ferrous metals, strip steel and plastics.

But the roots of Lindner Armaturen GmbH have not been forgotten either - the production of high-quality, innovative sanitary fittings is particularly close to the heart of today's managing director and co-partner, Mr Falk Höhne.

Since 2009, the development of customised fittings solutions for sanitary equipment, for the catering trade and for laboratory requirements, has once again formed a growing business segment of Lindner Armaturen GmbH. In addition to classic single-lever and infrared sanitary fittings in unusual designs, for example for equipping kindergartens and schools, Lindner is developing new types of practice-oriented fitting concepts such as the LINDNER MODULA concept, which has been available since 2012.

After Lindner had already developed new distribution systems with flow-drilled connections for the heating sector at the end of the 1990s, this was followed in 2004 by the market launch of its own completely new type of floor renovation system with integrable heating, which conquered the previously untapped market niche of underfloor heating systems in the modernisation of old buildings. The system, launched under the brand name "max4therm", is based on steel sheets and offers a highly load-bearing, solid, heated floor with an extremely low installation height and low weight.

Since 2007, the complete range of products, from insulation and underfloor heating support boards to screed, has been marketed independently under the "effidur" brand. Planning services and construction site support are naturally part of the service. The renovation solution, now known as the "effidur honeycomb panel system", has been able to establish itself throughout Europe and today has well-known references such as the Dresden Castle.

The increased demand required additional investment in the honeycomb panel production line. On a fully automated line, 400 t of rolled steel strip are processed annually. Further floor systems of the second product generation are in the market launch phase.

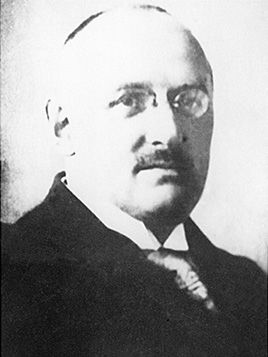

25.03.1883 - 06.06.1933

FELIX LINDNER

14.10.1911 - 20.03.1980

HEINZ LNDNER

GF 1991-2009

STEFAN LINDNER

GF SEIT 1997

FALK HÖHNE

GF SEIT 2022

FABIAN HÖHNE

| 2022 | Fully automated reinstallation of the punching line for the WP honeycomb panel system transferred to the Chemnitz production site. |

| 2021 | In-house development and new construction: Cutting and processing plant for air-conditioned ceiling profiles of the HK ceiling system. |

| 2020 | Start of production "nest production line" for hose production in Rabenstein, Insourcing punching line for WP production at the Rottluff site (from Eisenhüttenstadt), integration of the quality management system "CAQ system" throughout the company. |

| 2019 | Commissioning of "Rottluff production" with expanded machinery » CNC milling and turning centres Emco UMIL 750 and Index G200, Foundation of a separate unit for automation technology. |

| 2018 | Expansion of production site two in Chemnitz Rottluff, by an area of 10,000 m². |

| 2017 | Development and commissioning of the first fully automatic hose machine in Rabenstein. |

| 2016 | Lindner celebrates the 111th anniversary of the company's history, Visit by the Saxon Minister for Economic Affairs Martin Dulig. |

| 2015 | Increase in the export ratio to 30 percent of total turnover. |

| 2014 | Development of a safety mechanism to interrupt in case of defects in a water-bearing system, to prevent water damage. |

| 2013 | Expansion of the product portfolio to include special fittings for the kitchen, gastronomy and outdoor areas and product diversification for the successful children's fittings series "Lindino". |

| 2012 | Further development and implementation of the overall concept "barrier-free washbasin" (Material » solid surface material, with complete electronic control). |

| 2011 | Development and production of solid surface manufactured sanitary products. |

| 2010 | State-of-the-art production technology allows free-form production for the first time (Index R200 CNC turning/milling centre). |

| 2009 | Resumption of the production of high-quality sanitary fittings. |

| 2008 | Foundation of effidur GmbH " Development, production and distribution of the unique floor renovation system WP with with heating/cooling. |

| 2007 | Construction of a new production hall for hose manufacturing. |

| 2005 | Lindner celebrates its 100th anniversary. |

| 2001 | Expansion of the valve production, Lindner has six high-performance CNC machining centres. |

| 2000 | Certification according to DVGW quality management DIN EN ISO 9001:2000. |

| 1999 | Technoflex GmbH is merged with Lindner Armaturen GmbH. |

| 1994 | Expansion of the machinery, foundation of the independent company "Technoflex GmbH" for the assembly of sanitary and heating hoses. |

| 1992 | Purchase of the first CNC lathe INDEX GB 30. |

| 1991 | March » Dismissal of all employees by the VEB, June" New foundation of "Lindner Armaturen GmbH", August" Business operations are resumed. |

| 1975 | Affiliation with the Eisenberg Armaturenwerk combine; since then "VEB Armaturenwerk Eisenberg operating unit Karl-Marx-Stadt". |

| 1972 | Completion of the expropriation - after 67 years, the Lindner & Co. fittings factory becomes the "VEB Armaturenwerk Karl-Marx-Stadt". |

| 1958 - 1972 | Expansion of state shareholdings to about 80 %. |

| 1955 | Forced construction of a grey iron foundry. |

| 1952 | Conversion into a KG - 40 % of the business assets are transferred to public ownership. |

| 1939 - 1945 | Change to simple mass products due to the Second World War. |

| 1925 | Construction of a new foundry building. |

| 1915 | Resumption of production. |

| 1914 | Closure due to the First World War. |

| 1911 | Construction of an own metal foundry. |

| 1910 | Construction of a new factory building. |

| 1905 | Foundation of the "Armaturenfabrik Lindner & Böttcher, Rabenstein". |

LINDNER

ADRESS

Hauptstandort »

Lindner Armaturen GmbH

Kurze Straße 10

09117 Chemnitz

Tel » +49 371 23990

Fax » +49 371 8448208

Mail » info@lindner-armaturen.de

Werk Rottluff »

Lindner Armaturen GmbH

Weideweg 17

09116 Chemnitz